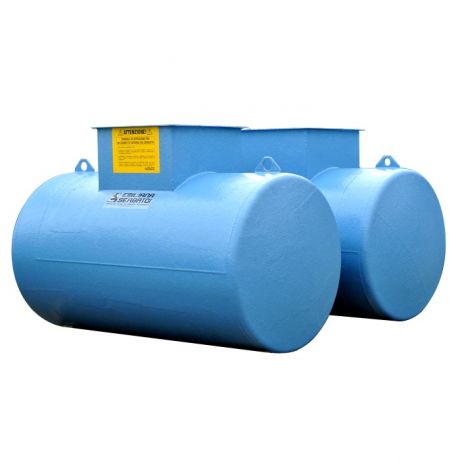

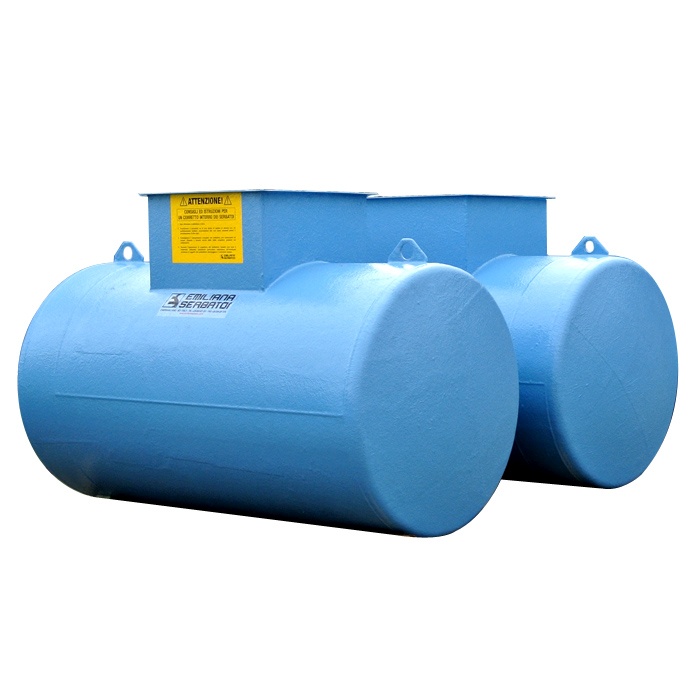

Underground tanks

Underground tanks

DESCRIPTION

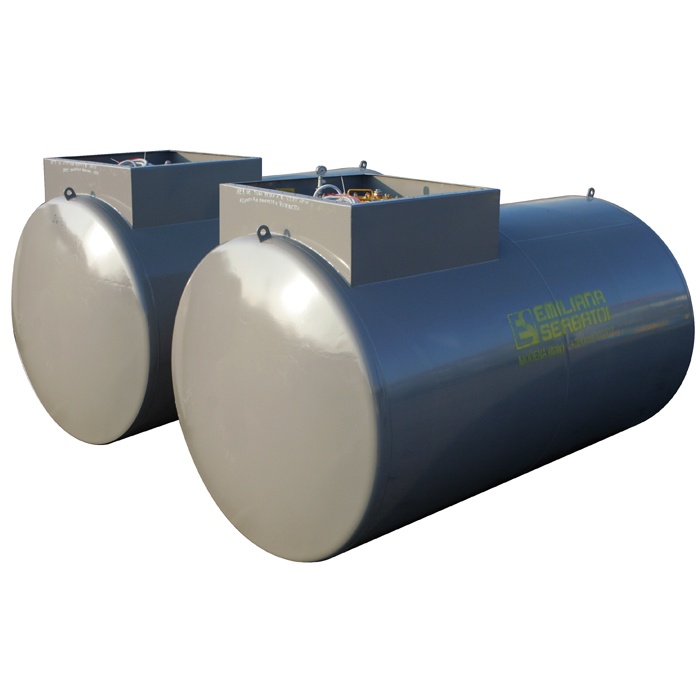

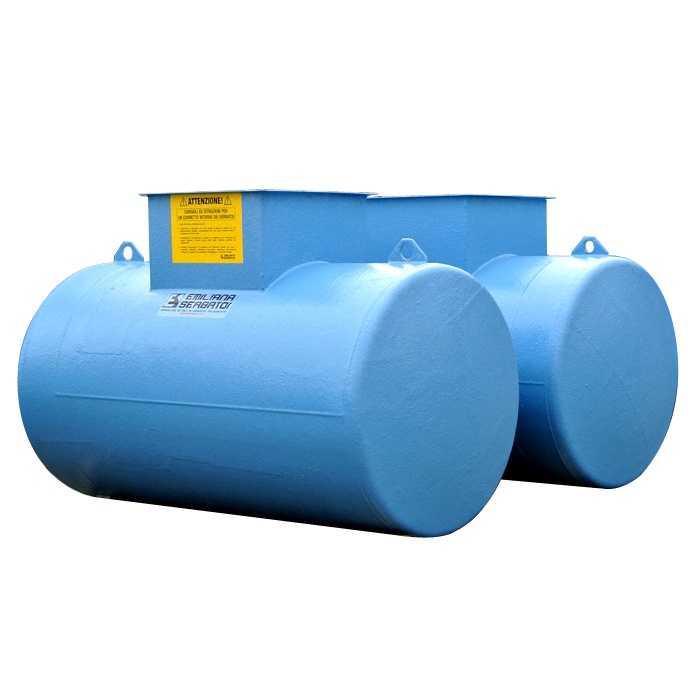

Horizontal cylindrical single and double-walled tanks for underground storage of flammable and non-flammable liquids. Made by using shell plates and dished ends made in carbon steel type S235JR complying with UNI EN 10025.

The external shell is welded by submerged arc welding procedure while the internal part is MIG-welded. Parts are designed in compliance with rules and regulations in force.

Single-walled tanks form an impermeable containment; they act as the inner tank of double-walled tanks.

Double-walled tanks; for these tanks, a secondary wall is welded around the inner tank, which forms an impermeable self-contained tank. These tanks are provided with two sockets for the leak detection system in order to permanently monitor the integrity of the tank.

All tanks are hydraulically tested. Tests are pressure tests and are performed to check the inner tank and the interstitial space between the inner and the outer tanks as well.

Fields of application:

Single-walled tanks are mainly used for:

- Fire-fighting systems.

- Irrigation systems.

- Collection and storage of rain water.

- Drinking water storage.

- Collection and storage of waste and effluent water.

- Storage of all kinds of liquids.

Double-walled tanks are generally used for:

- Service stations.

- Private fuel stations.

- Storage of flammable liquids for heating systems.

- Feeding generators.

- Storage of aircraft and ship fuels.

- Storage of chemicals and water-polluting liquids.

- Collection and storage of lubricants and drain oils.

- Collection and storage of waste and effluent water.

External coatings:

Each tank is provided with an external protection coating which also acts as cathodic protection.

The external coating of each tank undergoes a high-voltage test in order to prove its integrity.

POLYURETHANE: steel plates are sandblasted (SA 2.5 - ISO 8501-1) and coated with a type-868.06 grey polyurethane resin, applied hot, which consists in a polyurethane-made, 2-component, solvent-free coating meeting the NFE 86-900, DIN 6607 and DIN 4681 Part 3 standards.

This coating is a seamless protective film offering high tensile strength. Together with the excellent mechanical and chemical resistance of the material, it guarantees the best-in-class level of protection against external agents and a better preservation of the underground tank.

EPOXY-TAR: coated externally with epoxy-tar paint consisting in an epoxy-based, 2-component product made with epoxy resins modified by a coal tar-based hydrocarbon resin.

FIBERGLASS (GRP): steel plates are sandblasted (SA 2.5 - ISO 8501-1) and coated externally with a reinforced fiber-glass coating.

Internal coatings:

When an internal coating is required, tank's inner surface is prepared in accordance with the customer's requirement and the coating manufacturers specifications to ensure permanent adhesion of the selected coating. On request we can provide the following internal surface coating:

- Internal coating for non-drinking water: steel surface is sandblasted (SA 2.5 - ISO 8501-1) and coated with an anticorrosive layer of epoxy-based two-components resin.

- Internal coating for drinking water: steel surface is sandblasted (SA 2.5 - ISO 8501-1) and coated with a bicomponent polyammine epoxy coating which is certified by the Ministry of Health for prolonged contact with drinking water and food.

- Internal coating for aviation fuels: steel surface is sandblasted (SA 2.5 - ISO 8501-1) and coated with a light coloured epoxy-phenolic resin free from zinc, cadmium and copper alloys.

Main accessories:

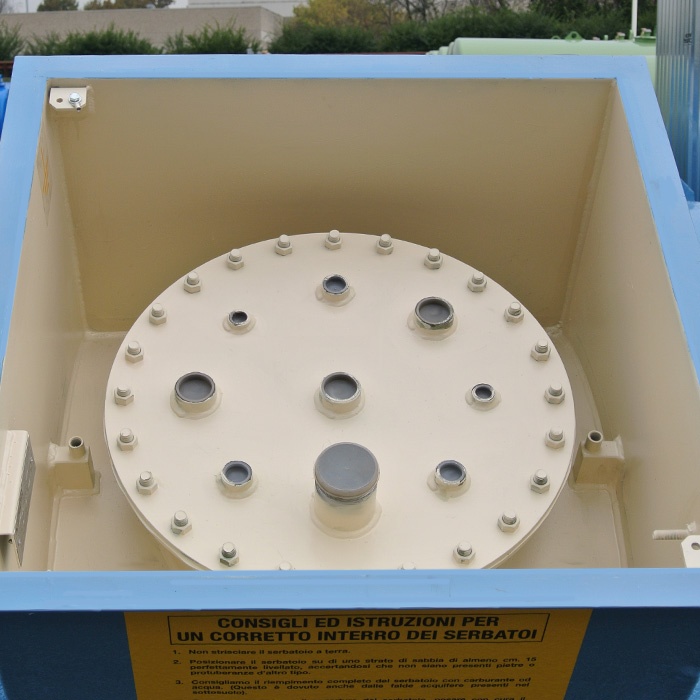

- Ø 600 mm (or different dimension if specified by the purchaser) access manhole complete with gasket and bolted cover.

- Loading access port with lockable quick cap and overfill protection valve.

- Vent equipped with flame arrestor net.

- Suction line provided with foot valve and strainer.

- Aluminium-made dip stick calibrated gauge to measure manually the fuel level.

- Wide range of mechanical or electronic level gauges.

A wide range of pumps and fuel meters to meet a large range of requirements and applications. Optionally can be installed a fuel management system to control fuelling operations and tank level.

Leak monitoring systems:

-

LAG14ER: is a leak detection system, connected to the double wall inlet connection. The interstitial space is filled with anti-freeze mono-propylene glycol solution, which is non-toxic and not-polluting.

-

EUROVAC: Eurovac NV is a vacuum leak detector according to EN 13160-1 for Class 1. Through the suction hose the vacuum pump fitted in the leak detector generates a depression in the monitoring interstitium of the tank which is maintained constant in time. When a leak occurs in the internal or external wall of the tank, the depression lowers. On reaching the switching point, the red light “alarm” together with the audio alarm turn on.

- EUROPRESS: pressure type leak detector according to EN 13160 (class I) for safe monitoring of unpressurised double-walled tanks for the storage of inflammable liquids, AdBlue® (urea solution 32.5%) and non-inflammable, water-polluting liquids. Tanks may be located in safe or hazardous areas, either above or underground. The tank interstitial space is pressurised via an internal pump to 510mbar. A leak in either the inner or outer skin results in a pressure drop in the tank interstitial space, initiating a visual and audible alarm.

Documents & Certificates:

- Testing and tank certificate.

- EC Conformity certificate of the pump unit (if supplied).

- Tank's Calibration table.

- Certificate and manual for the use of the monitoring system.

DOWNLOAD

The specifications may differ from areas and we keep the right to change without notice. Please check the specification with your local dealers. The color of the product might be affected by photography and the monitor's setting, which might be different from the real product.